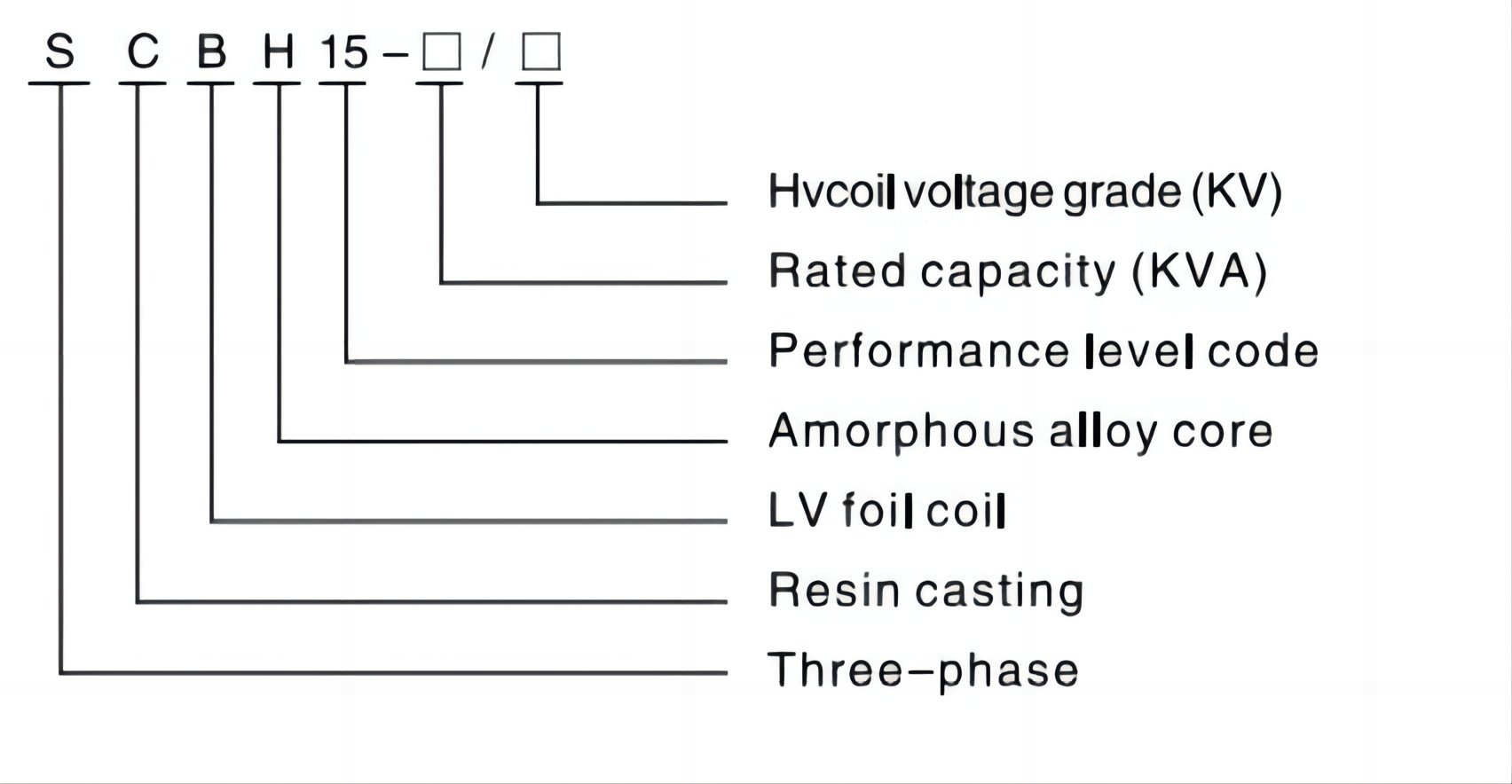

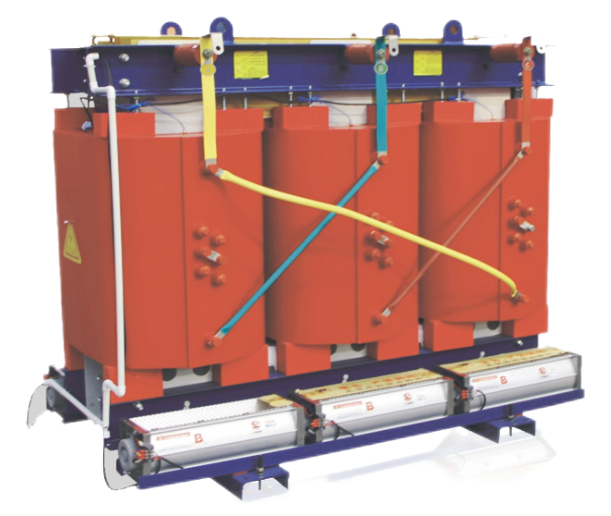

SCBH15 series amorphous alloy dry transformer has such advantages as low no-load loss, no oil, flame retardant, self-extinguishing, moisture-free, and maintenance-free. Now, the amorphous alloy transformers are applied to all sites(including airports, railway stations, metros, high-rise buildings, and power plants)where normal dry transformers are applied, and especially they are more appropriate for places with flammable, explosive, and power shortages. The specific features are as follows:

1. Low consumption and energy-saving: the permeability magnetic materials with isotropic soft magnetism are used, with small magnetizing power, high resistivity, and low eddy current loss. The core made of amorphous alloy has low no-load loss and no-load current, only one-third of silicon steel sheets. The no-load loss of the transformer falls 75% compared to the value provided in GB/T10228. It can significantly reduce operating costs and the energy-saving effect is significant.

2. Strong corrosion resistance: the amorphous alloy core is fully encapsulated with resin and heat-resistant silicone, thus effectively preventing rust and amorphous alloy debris shedding, to protect the core and coils effectively.

3. Low noise: to reduce the running noise, a reasonable working flux density is selected in the product design; before product processing, the core and coil structure are improved, and special noise-reducing materials are used, so that the noise of the product is well below the requirement of the national standard JB/T10088.

4. Strong ability to withstand short circuits: the products adopt three phases three limb structure, adopts a frame structure spread around the core, reasonably compact.

5. Low-temperature rise and long service life: the product has low-temperature rise and strong heat-sinking capability, and can run with 150% of the rated load under the condition of forced air cooling. A temperature control protection system with perfect performance can be selected and adapted to provide reliable protection for the safe operation of the transformer.

ProductWe will always adhere to the "mutual benefit and win-win" concept of cooperation, customer demand oriented,customer satisfaction as the goal, to provide customers with reliable products and super expected service.MORE

ProductWe will always adhere to the "mutual benefit and win-win" concept of cooperation, customer demand oriented,customer satisfaction as the goal, to provide customers with reliable products and super expected service.MORE

SolutionsProducts are widely used in power, communication, chemical, mining, metallurgy, transportation, petroleum, railway and other important fields.MORE

SolutionsProducts are widely used in power, communication, chemical, mining, metallurgy, transportation, petroleum, railway and other important fields.MORE ServiceWe will continue to take quality management as the core, high-tech as the guidance, with customers at home and abroad to establish strategic partnership, win-win cooperation, create a better future!MORE

ServiceWe will continue to take quality management as the core, high-tech as the guidance, with customers at home and abroad to establish strategic partnership, win-win cooperation, create a better future!MORE About UsPeople Electrical Appliance Group is one of China top 500 enterprise and Global Top 500 machinery company.MORE

About UsPeople Electrical Appliance Group is one of China top 500 enterprise and Global Top 500 machinery company.MORE