(一)PVC insulated power cables rated up to 0.6/1kV

Model、description and application

| Model |

Description |

Application |

VV

VLV |

PVC insulated & sheathed power cables |

For laying in doors or tunels, but unable to bear pressure andexternal mechanical forces |

VV22

VLV22 |

PVC insulated & sheathed, steel tape armored power cables |

For laying in doors, in tunels or underground, can bearpressure and external mechanical forces |

VV32

VLV32 |

PVC insulated & sheathed, fine steel wire armored power cables |

For laying in doors, in wells or under water, can bear certain pulling force. |

VV42

VLV42 |

PVC insulated & sheathed, heavy steel wire armored power cables |

For laying down wells or under water, can bear certain pullingforce. |

NH ZR-VV

ZR-VLV |

PVC insulated & sheathed, flame retardant & fire resistant cables |

For laying in doors or tunels, but unable to bear pulling forceand pressure. On the sites where fire occurs frequently. |

NH ZR-VV22

ZR-VLV22 |

PVC insulated & sheathed, steel tape armored, flame retardant

& fire resistant cables |

For laying in doors, in tunels or underground, can bear pullingforce and pressure. On the sites where fire occurs frequently. |

NH ZR-VV32

ZR-VLV32 |

PVC insulated & sheathed, fine steel wire armored, flame retardant

& fire resistant cables |

For laying in doors, in wells or under water, can bear certainpulling force. On the sites where fire occurs frequently. |

NH ZR-VV42

ZR-VLV42 |

PVC insulated & sheathed, heavy steel wire armored, flame retardant

& fire resistant cables |

For laying down wells or under water, can bear certain pullingforce. On the sites where fire occurs frequently. |

L—Aluminium conductor

Product range

| Model |

No. of cores |

Rated voltage up to 0.6/1kV |

| Naminal cross-section mm2 |

| Cu |

AI |

VV VLV NH ZR-VV ZR-VLV

VV62 VLV62 NH ZR-VV62 ZR-VLV62

VV62 VLV62 NH ZR-VV62 ZR-VLV62 |

1 |

1.5 ~ 630

4 ~ 630

16 ~ 630 |

2.5 ~ 630

10 ~ 630

25 ~ 630 |

VV VLV NH ZR-VV ZR-VLV

VV22 VLV22 NH ZR-VV22 ZR-VLV22

VV32(42) VLV33(42) NH ZR-VV32(42) ZR-VLV32(42) |

2 |

1.5 ~185

4~185

6~185 |

2.5 ~ 185

6 ~ 185

10 ~ 185 |

VV VLV NH ZR-VV ZR-VLV

VV22 VLV22 NH ZR-VV22 ZR-VLV22

VV32(42) VLV33(42) NH ZR-VV32(42) ZR-VLV32(42) |

3 |

1.5 ~ 300

4 ~ 300

6 ~ 300 |

2.5 ~ 300

6 ~ 300

10 ~ 300 |

VV VLV NH ZR-VV ZR-VLV

VV62(62,62) VLV62(62,62)

NH ZR-VV62(62,62) ZR-VLV62(62,62) |

3+1;4 |

1.5 ~400

2.5 ~300 |

6 ~ 300 |

VV VLV NH ZR-VV ZR-VLV

VV22(32,42) VLV22(32,42)

NH ZR-VV22(32,42) ZR-VLV22(32,42) |

5;4+1;3+2 |

1.5 ~400

2.5 ~300 |

6 ~ 300 |

The sinole core amored cables are used in DC system only. If in AC system, t should use the armored layer of non-magnetic materal or magnetic isolation

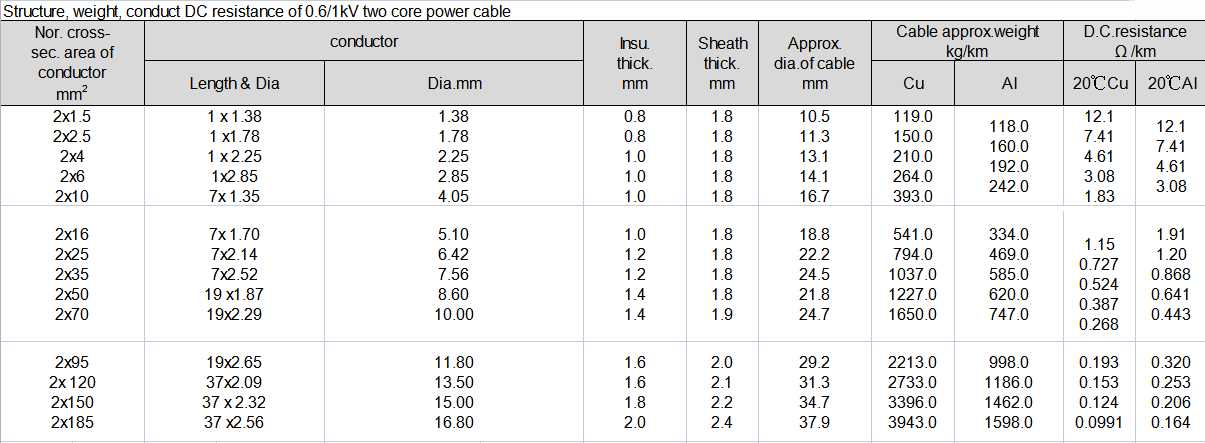

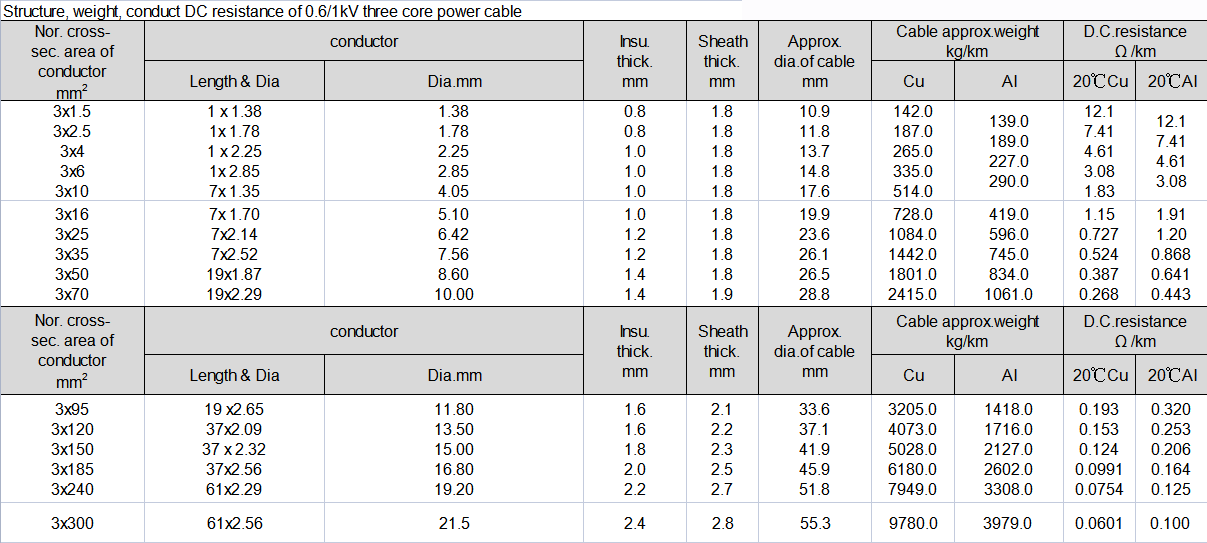

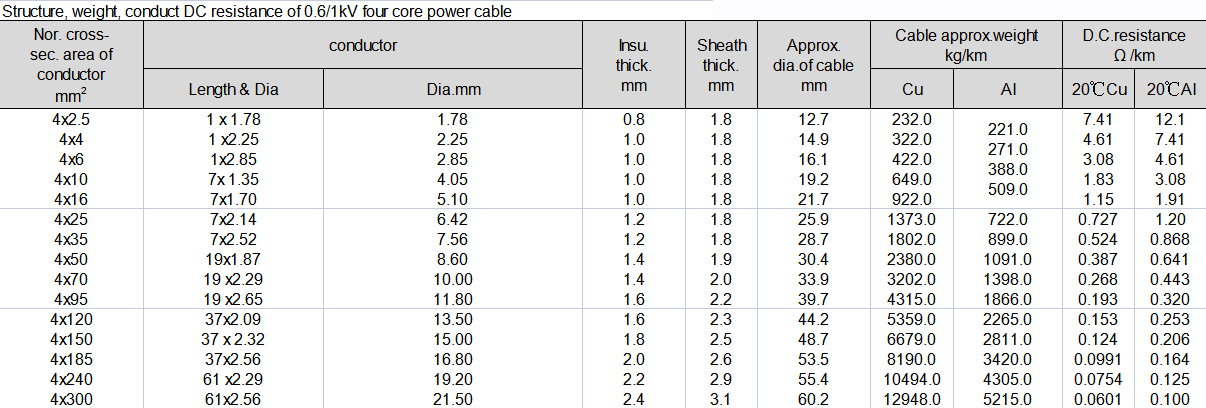

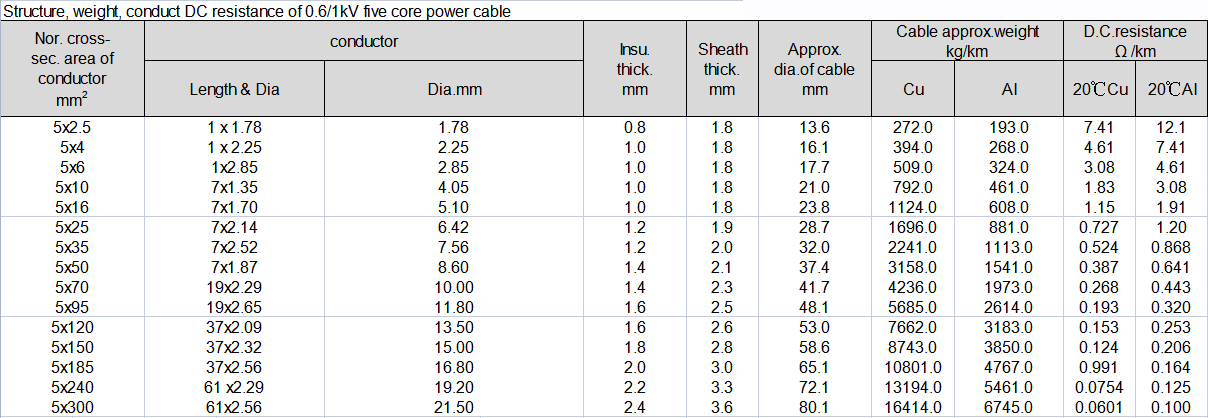

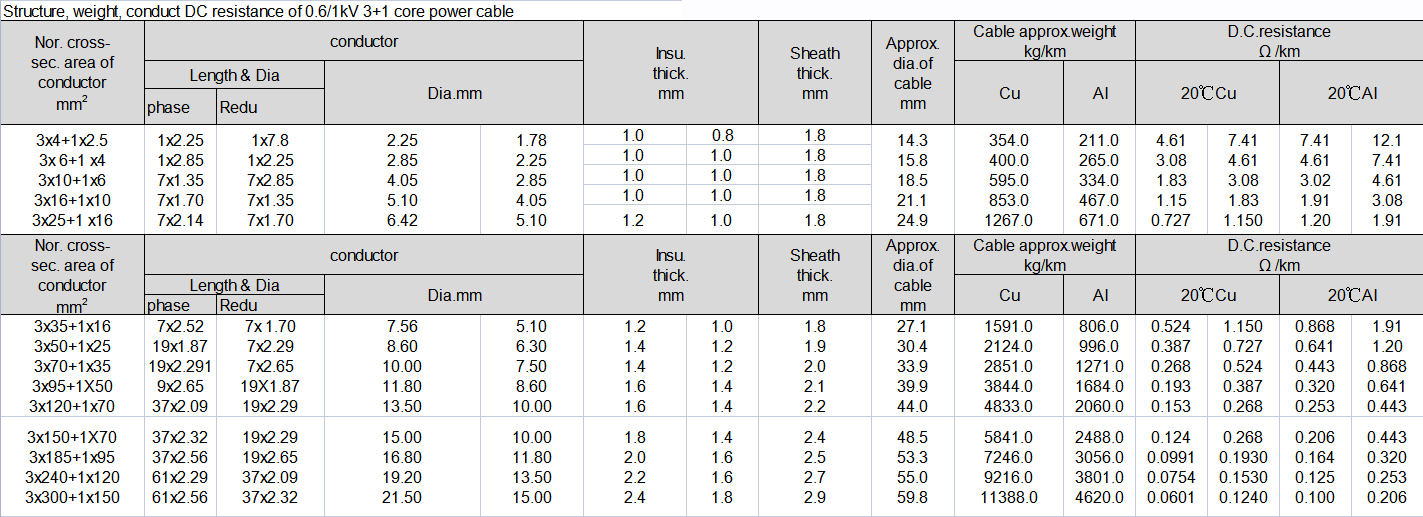

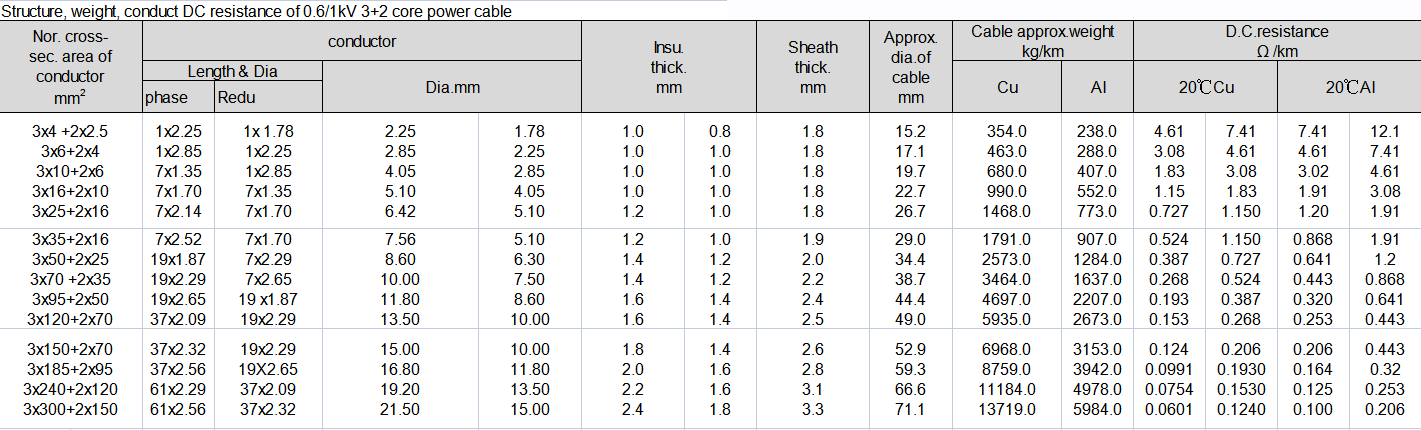

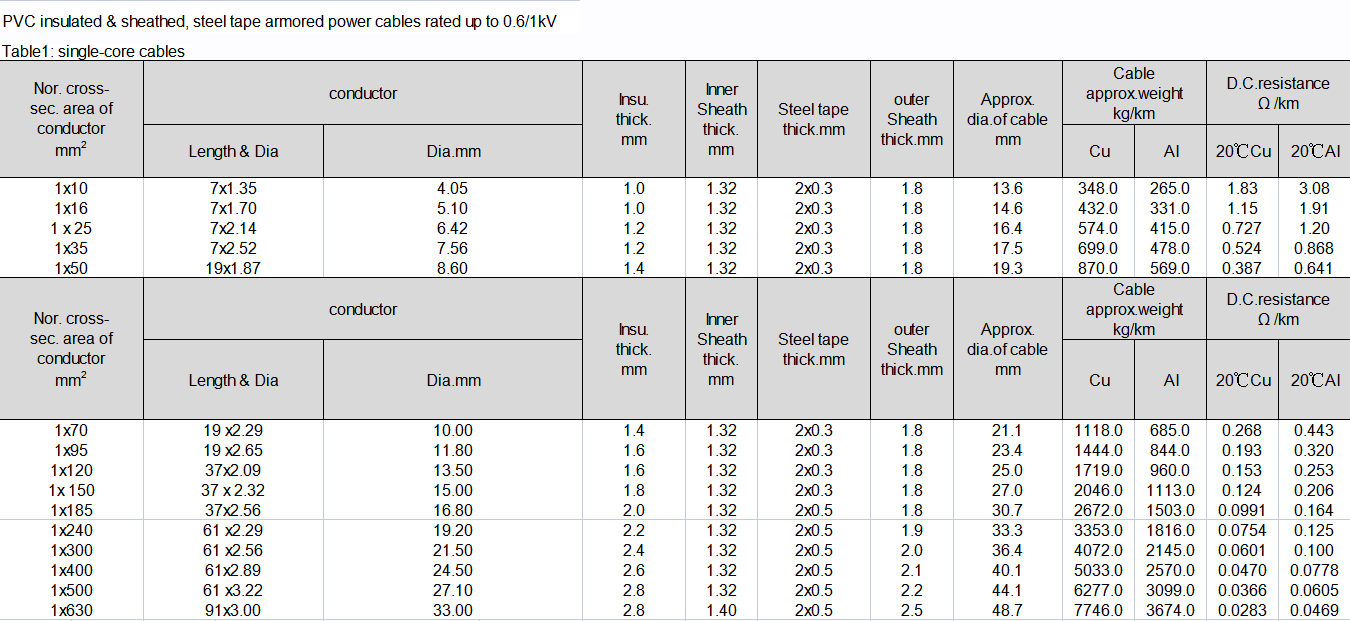

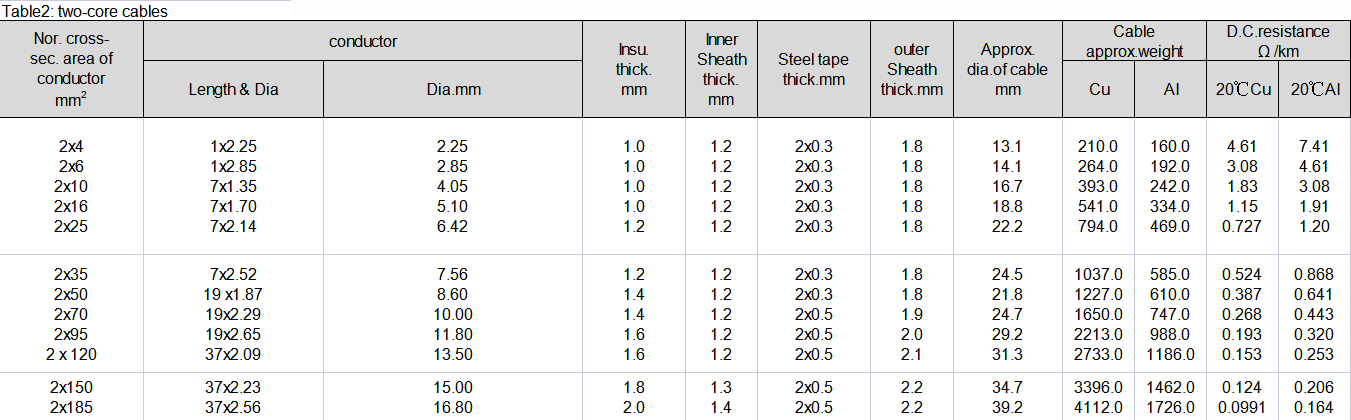

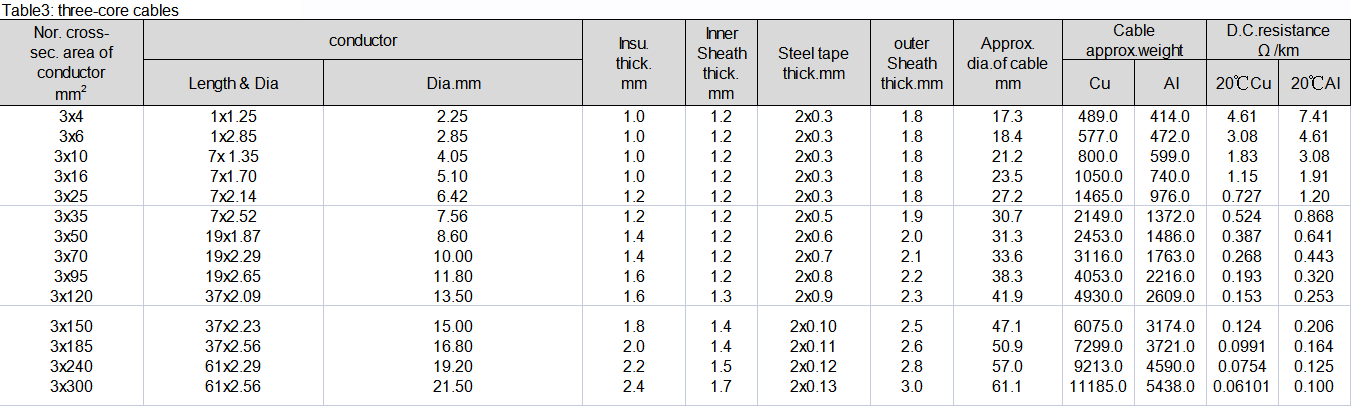

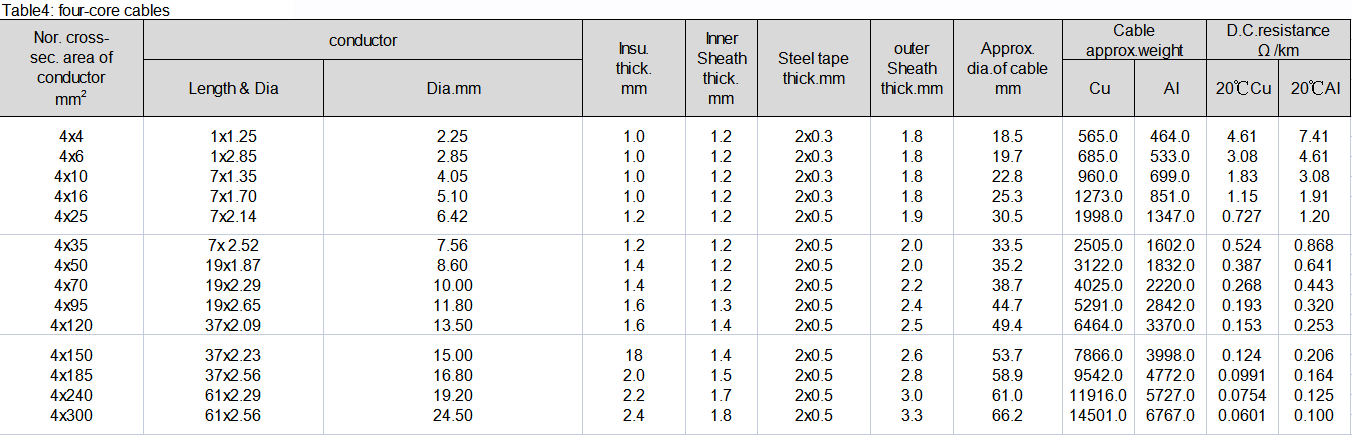

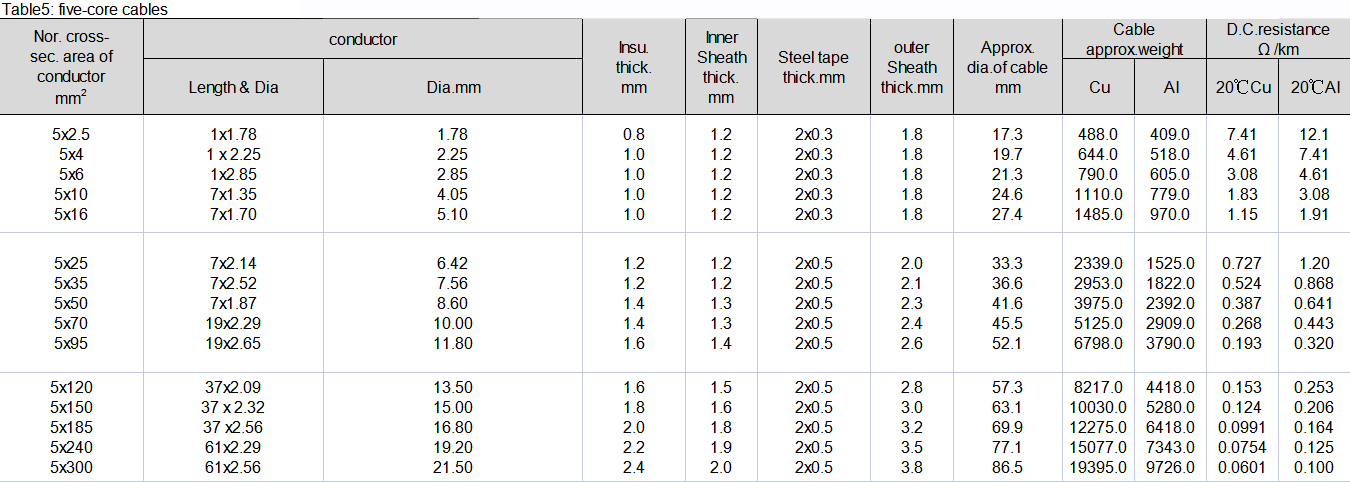

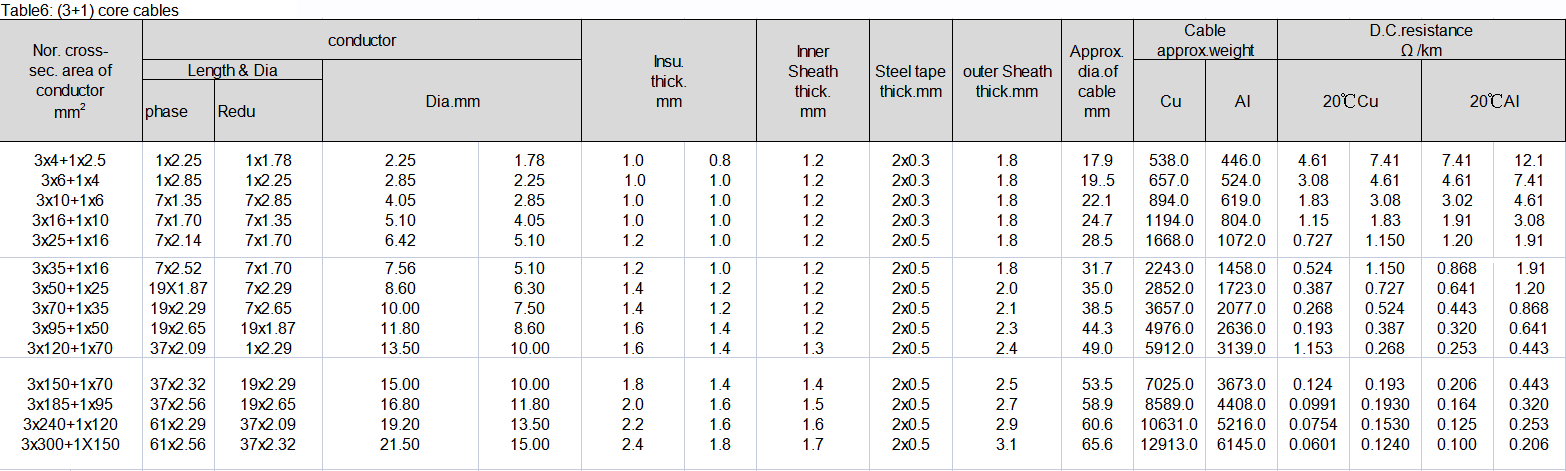

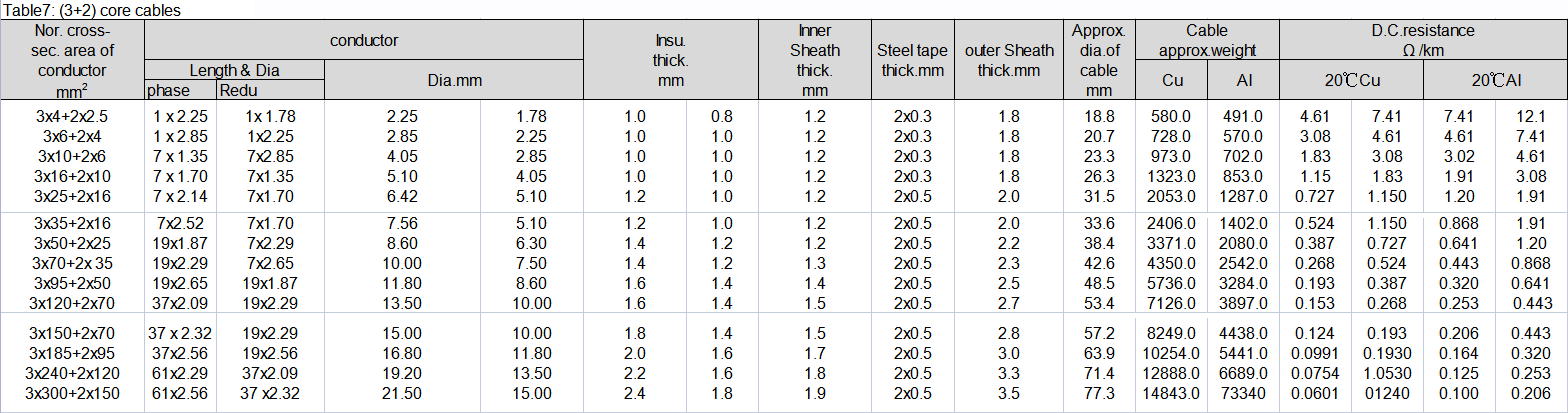

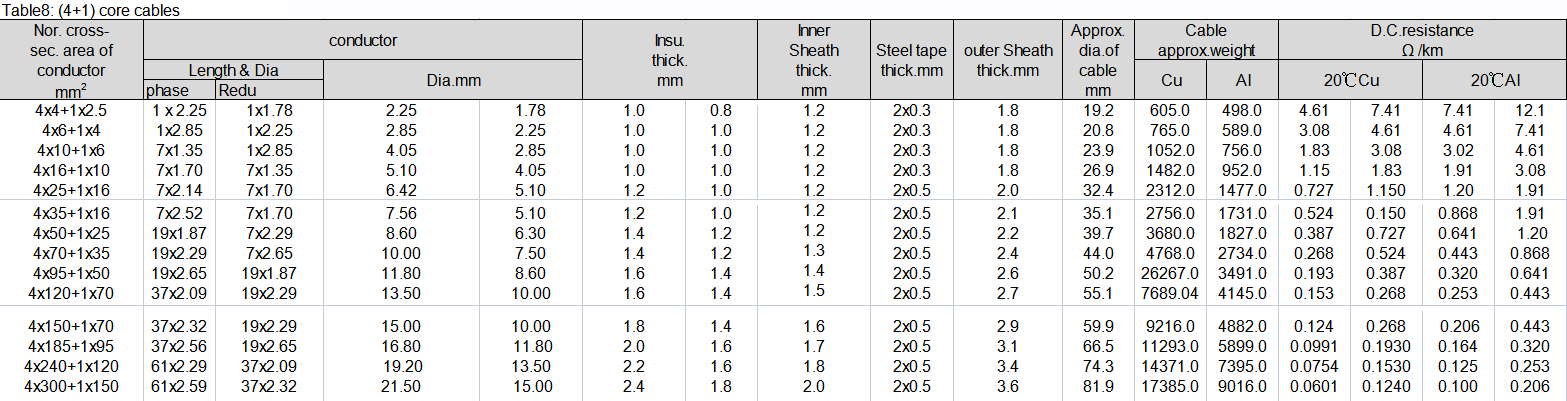

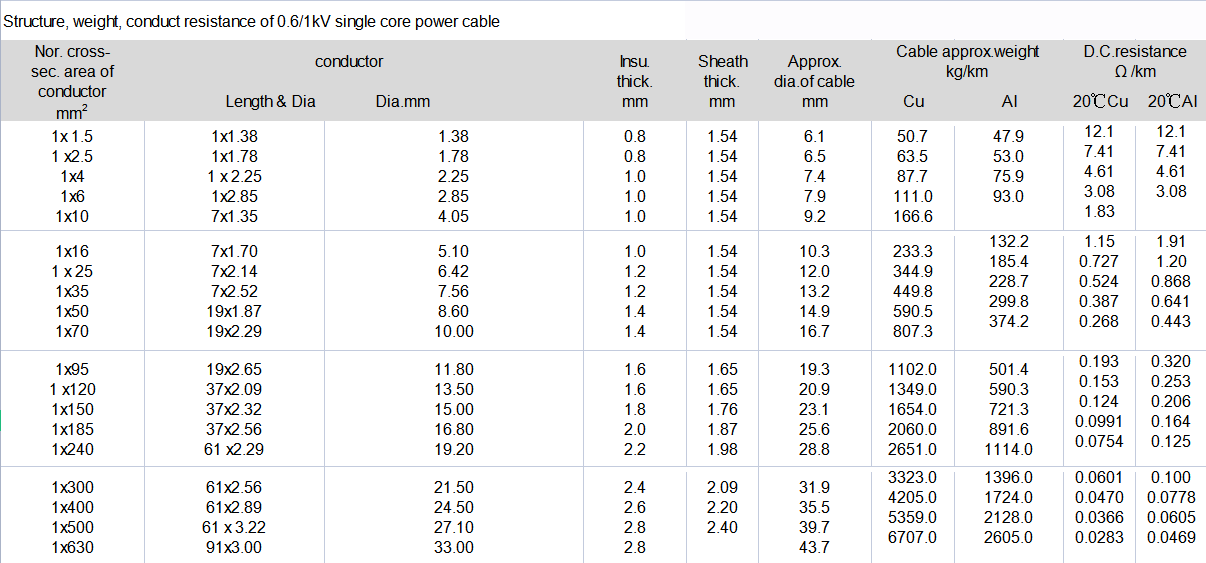

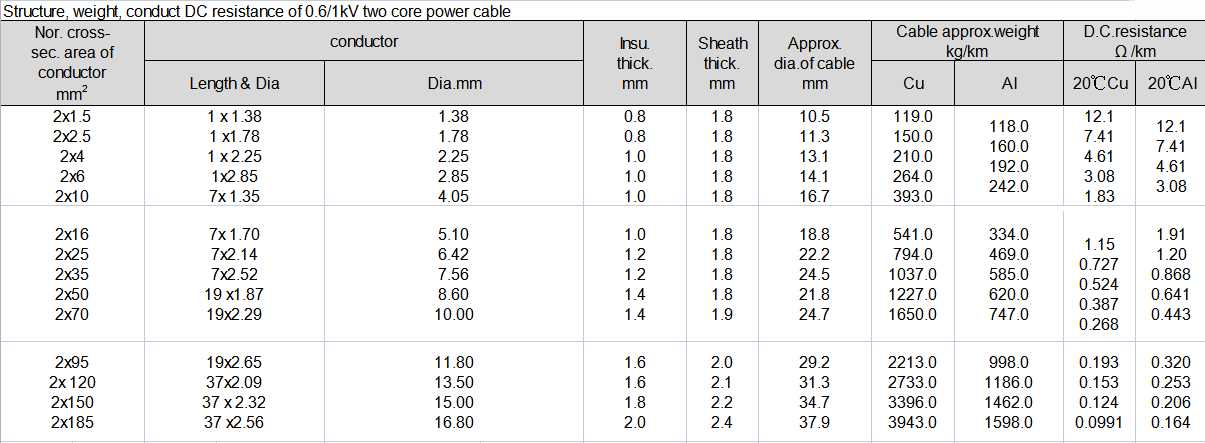

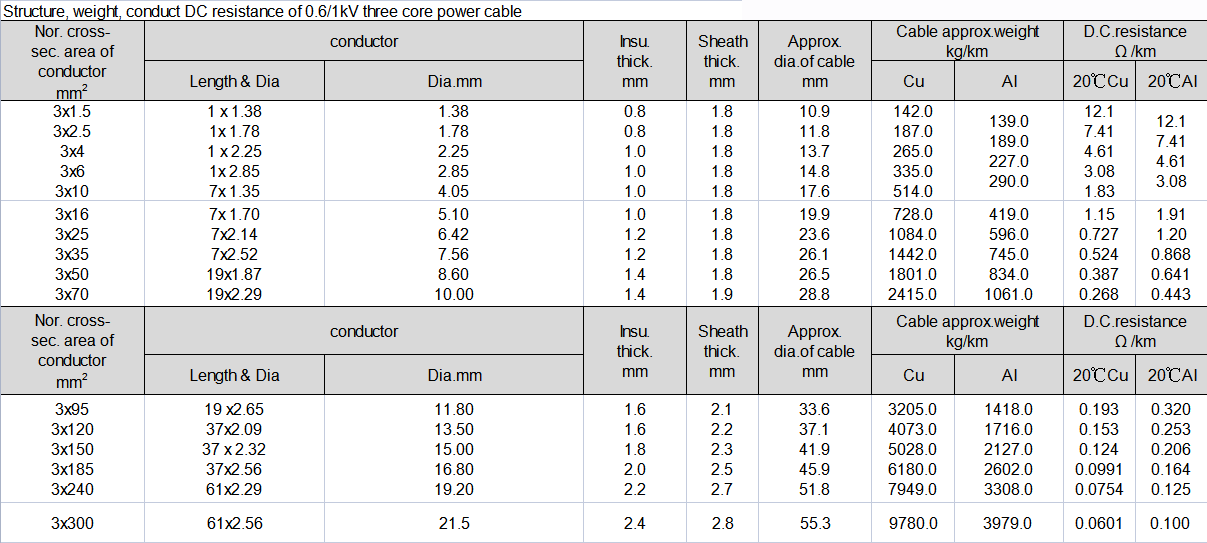

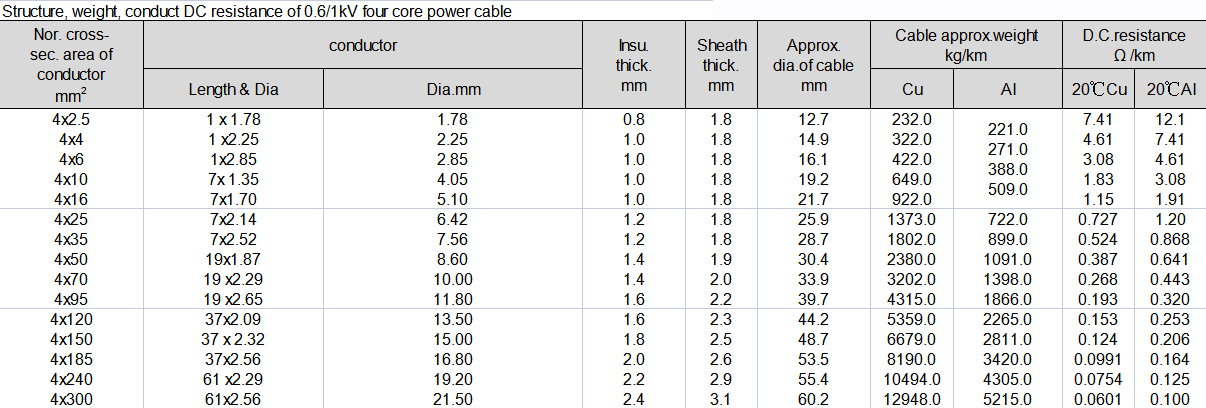

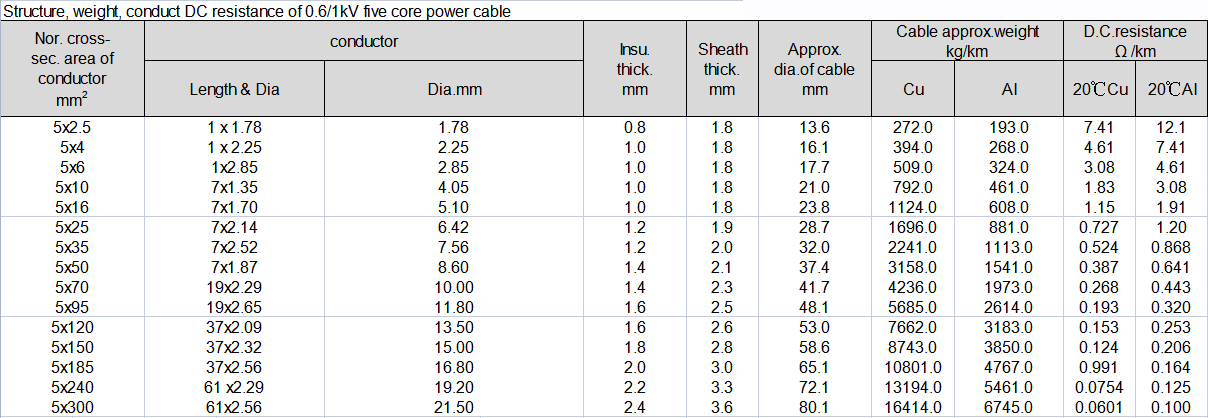

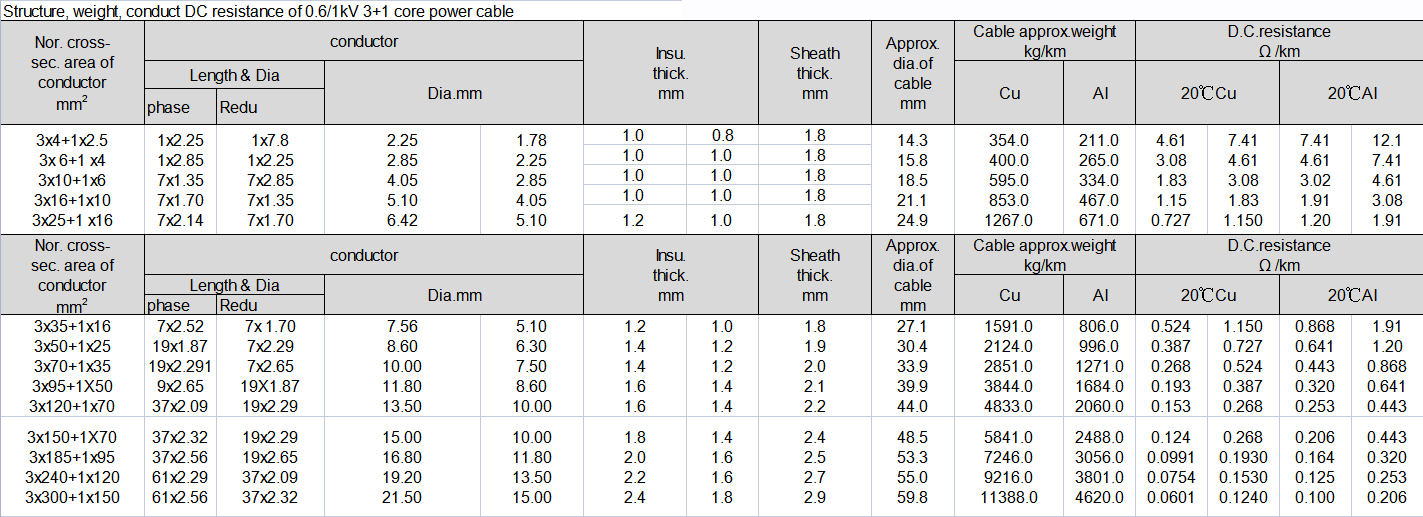

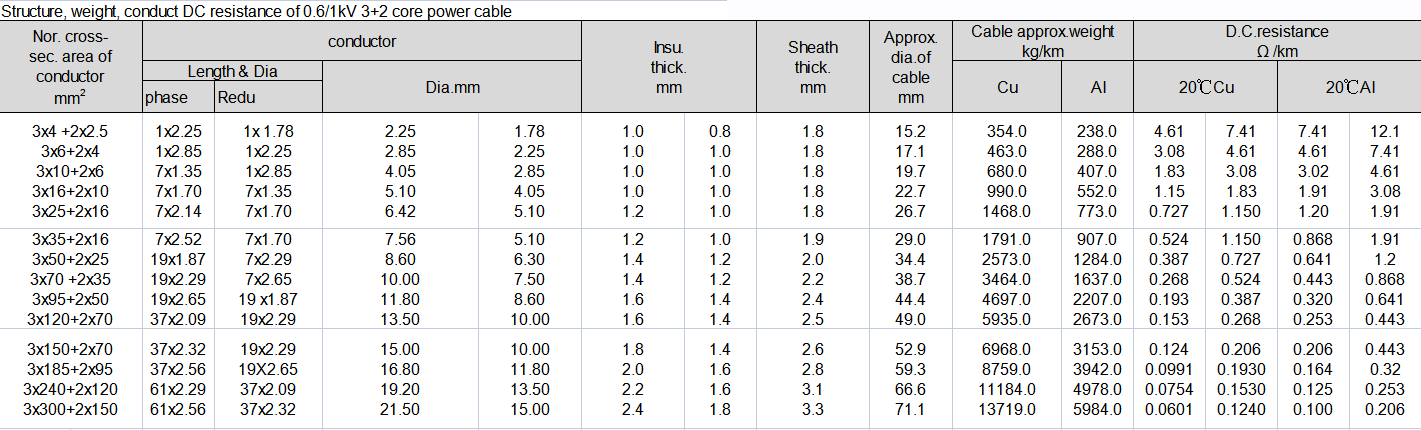

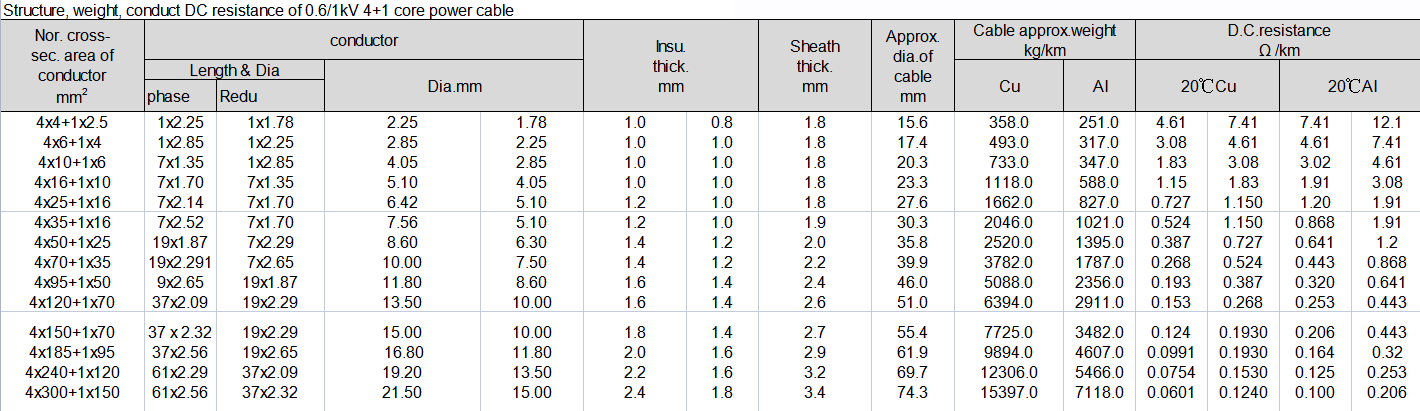

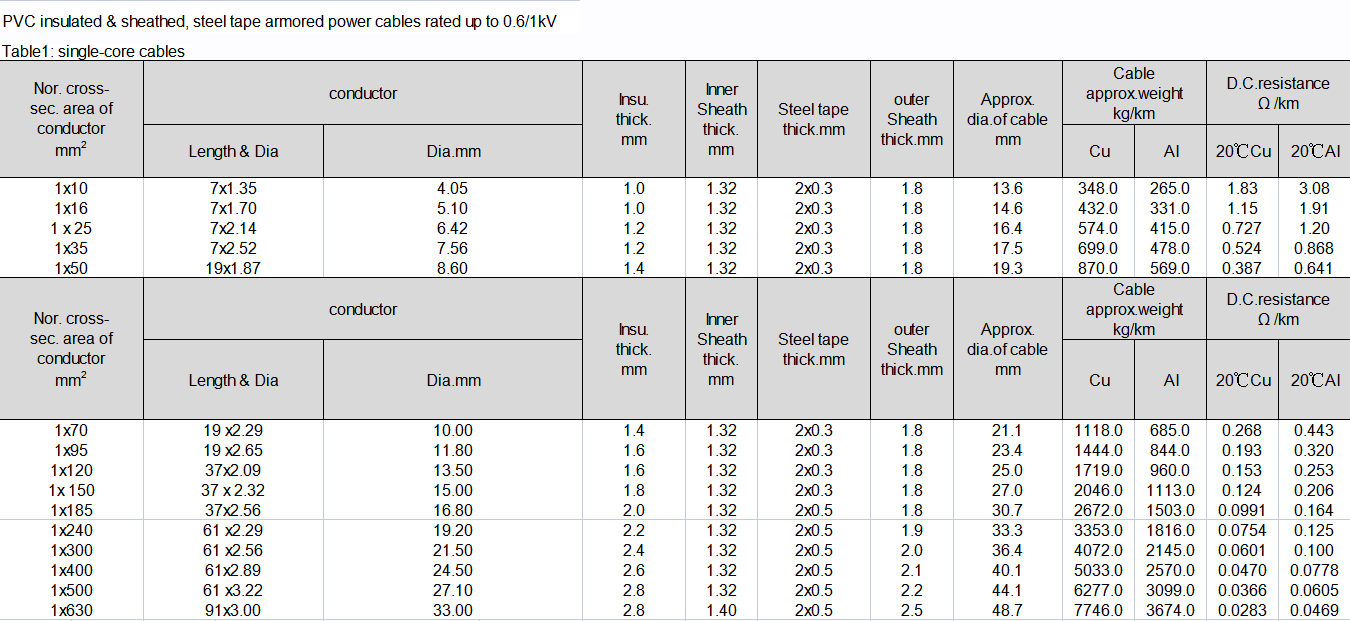

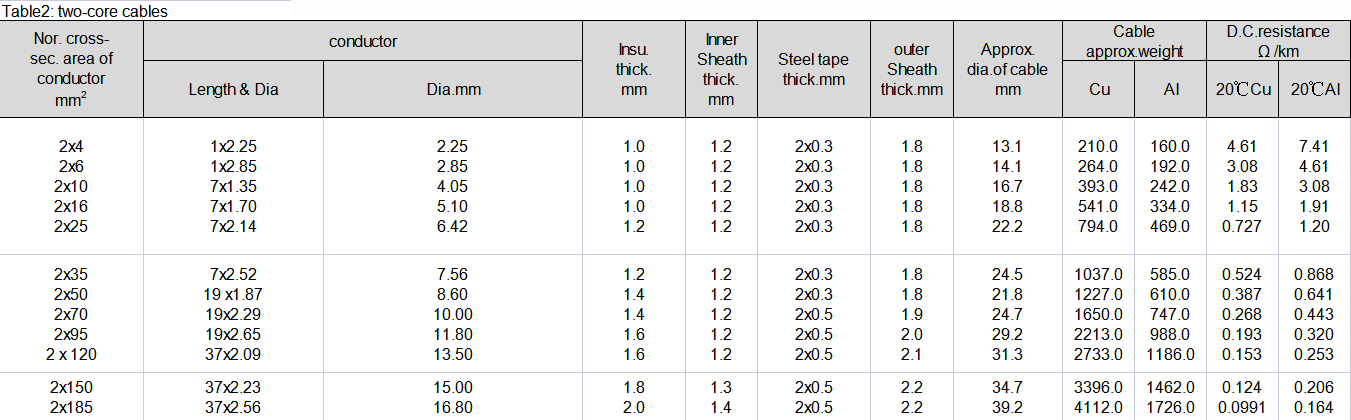

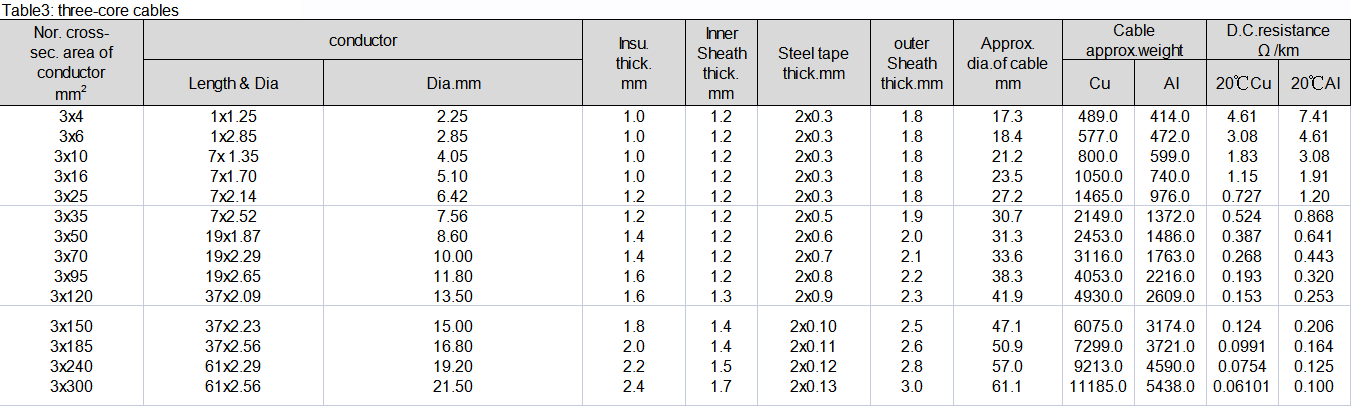

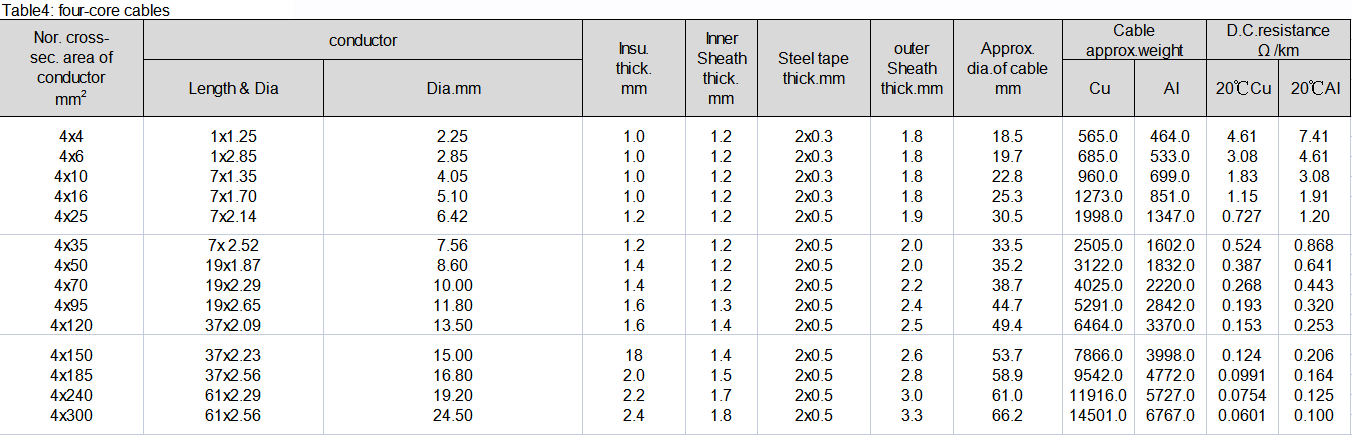

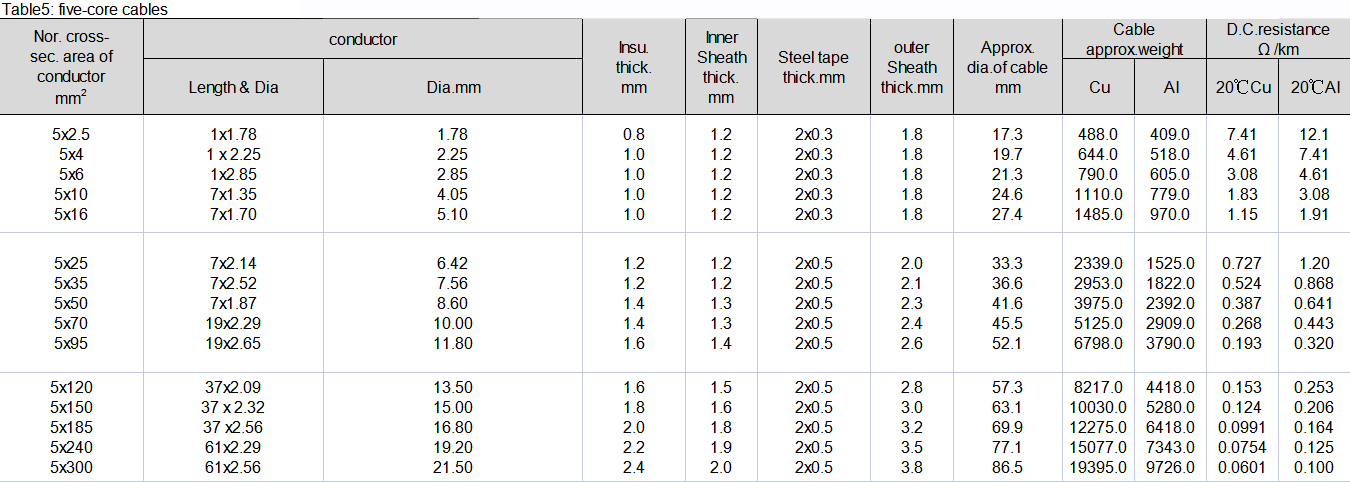

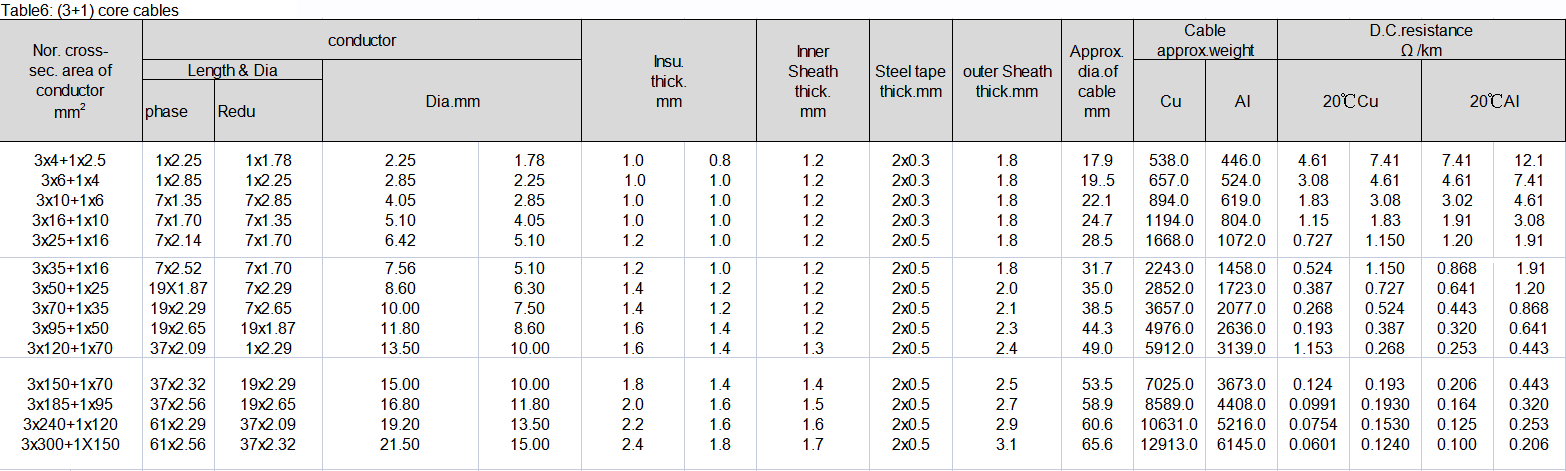

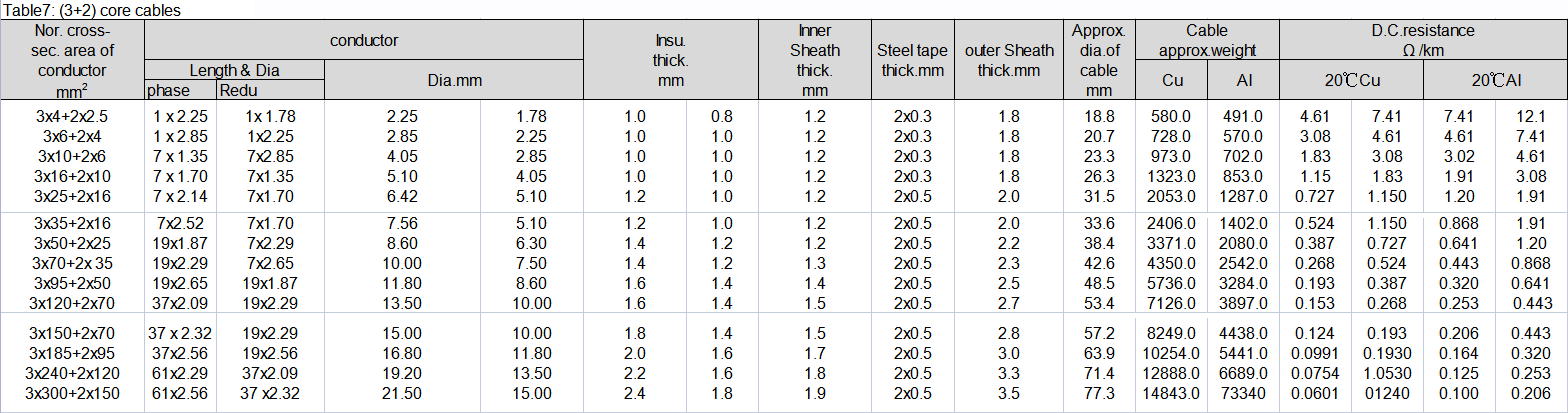

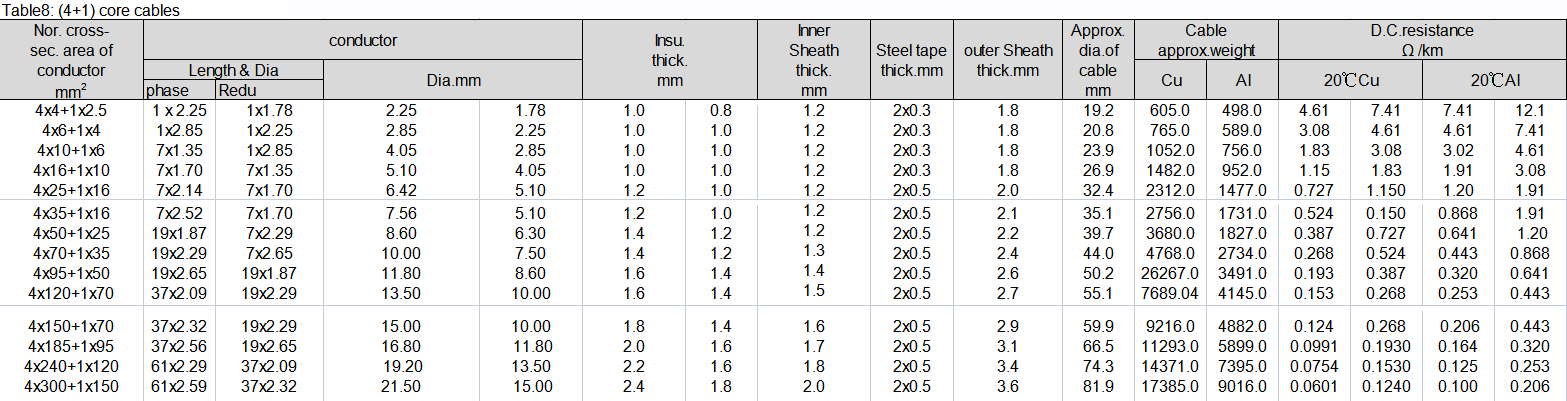

Structure, technical data are listed in table1-8,except for conductor diameter.

Main properties

| No. |

Test item |

Property |

| 1 |

Structure |

Listed to the tables |

| 2 |

Conductor resistance |

Listed to the tables |

| 3 |

Withstand voltage test A.C.3.5kV 5min |

No breaken |

| 4 |

Mechanical

properties

before aging |

Tensile strength |

Insulation |

Min.12.5N/mm2 |

| Sheath |

Min.12.5N/mm2 |

| Elongation at break |

Insulation |

Min.150% |

| Sheath |

Min.150% |

Mechanical

properties and

flame-retardantproperties after

aging |

Tensile strength |

Insulation |

100C+2℃7days Min.12.5N/mm2 |

| Sheath |

100C+2℃7days Min.12.5N/mm3 |

| Varying valve of tensile strength |

Insulation |

100C土2℃7days Max.土25% |

| Sheath |

100C土2℃7days Max.土26% |

| Elongation at break |

Insulation |

100C土2℃ 7days Min.150% |

| Sheath |

100C土2℃ 7days Min.151% |

| Varying valve of tensile strength |

Insulation |

100C土2℃7days Max.土25% |

| Sheath |

100C土2℃7days Max.土25% |

| 5 |

Flame-retardant property |

Comply with GB12660.5-90(CB)and IEC332-3(CB) |

| 6 |

Constant of insulation resislivity |

Min at20℃ |

36.7 |

| Ki MQ km Ki M&. km |

Min at70℃ |

0.037 |

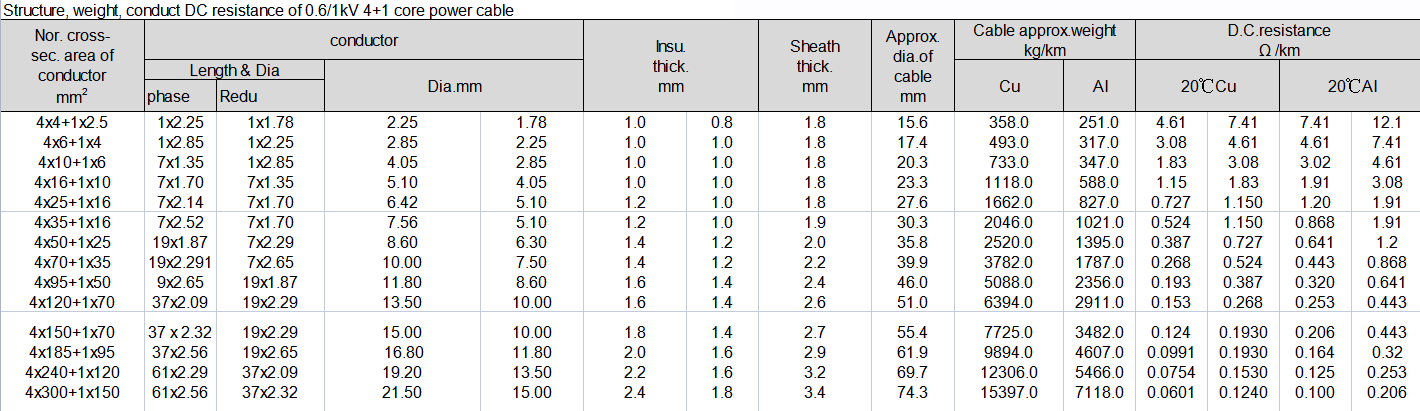

PVC insulated & sheathed power cables rated up to 0.6/1kV

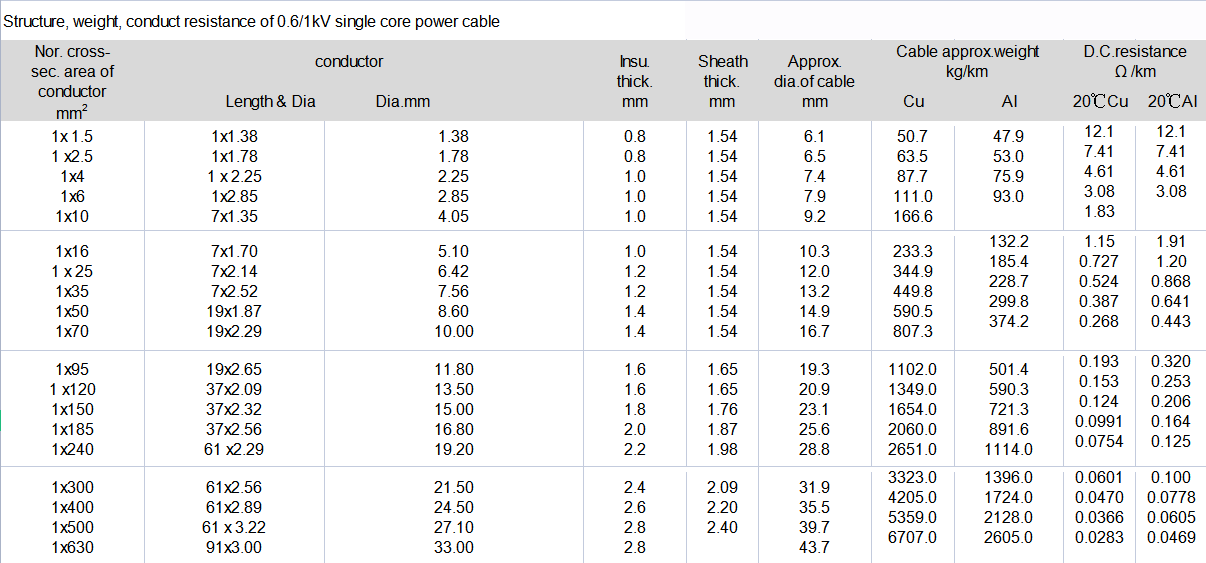

Structure, weight, conduct resistance of 0.6/1kV single core power cable

Cable laying conditions and long-term loading allowed ampacity

Installation

The installation temperature should not be lower than 0℃, lf the ambient temperature is lower than 0℃ , the cableshould be preheated.

The bending radius of cable should not less than 10-15 times

After installation, the cable should withstand voltage test for15 min. 3.5Kv d.c.

In air

The sinale core cable aying in parallel,the distance between the cable’s center is 2 imes(for cables, which cross sectional area of conductor<185mm and90 mm (for cables, which cross sectional area of conductor>240mm’)。

Ambient temperature: 40℃

Max.temperature of conductor: 70℃

Rating factors under different ambient temperature :

| Air temperature |

20℃ |

25℃ |

35℃ |

40℃ |

45℃ |

| Rating factors |

1.12 |

1.06 |

0.94 |

0.87 |

0.79 |

Directly buried into ground

When the single core cables are installed separately,the distance between the cable’s center is 2 times of the cable diameter.

Ambient temperature: 25℃

Max,temperature of conductor: 70℃

Soil thermal resistivitv: 1.0℃ mW

Depth: 0.7m.

Rating factors under different ambient temperature

| Air temperature |

15℃ |

20℃ |

30℃ |

35℃ |

| Rating factors |

1.11 |

1.05 |

0.94 |

0.88 |

Short circuit ratings

| Max.temperature at short circuit |

Maxshort circuit current |

| 130℃ |

l=94s //tA |

Where: S–corss sectional area of conductor(mm?) t–short circuit duration(sec).

ProductWe will always adhere to the "mutual benefit and win-win" concept of cooperation, customer demand oriented,customer satisfaction as the goal, to provide customers with reliable products and super expected service.MORE

ProductWe will always adhere to the "mutual benefit and win-win" concept of cooperation, customer demand oriented,customer satisfaction as the goal, to provide customers with reliable products and super expected service.MORE

SolutionsProducts are widely used in power, communication, chemical, mining, metallurgy, transportation, petroleum, railway and other important fields.MORE

SolutionsProducts are widely used in power, communication, chemical, mining, metallurgy, transportation, petroleum, railway and other important fields.MORE ServiceWe will continue to take quality management as the core, high-tech as the guidance, with customers at home and abroad to establish strategic partnership, win-win cooperation, create a better future!MORE

ServiceWe will continue to take quality management as the core, high-tech as the guidance, with customers at home and abroad to establish strategic partnership, win-win cooperation, create a better future!MORE About UsPeople Electrical Appliance Group is one of China top 500 enterprise and Global Top 500 machinery company.MORE

About UsPeople Electrical Appliance Group is one of China top 500 enterprise and Global Top 500 machinery company.MORE