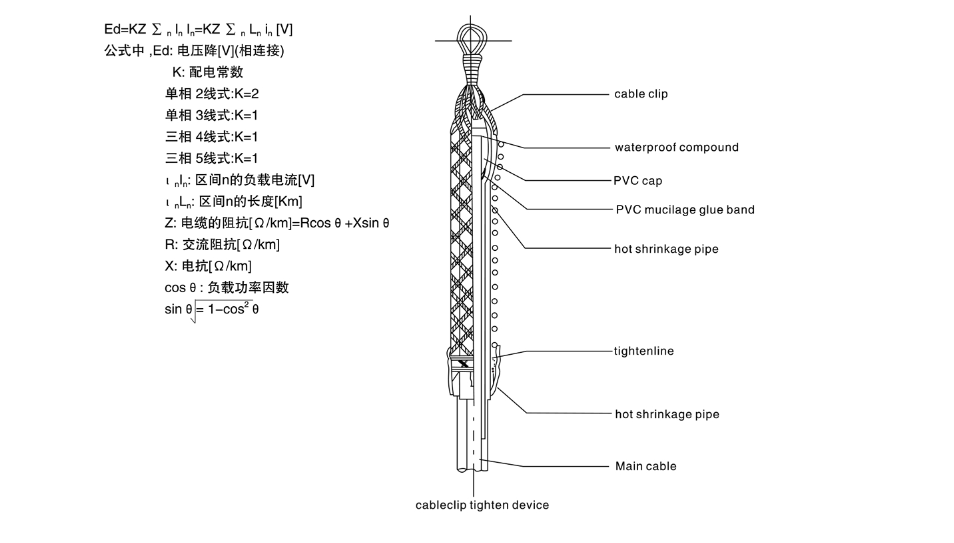

1.Insulation resistance >200MQ;

2.InsulatiOn withstand Voltage>3.5kV/5min;

3.Excellent air tightness and water proofing quality. When immerge branch joint water, measured insulationresistance between water and cable core, and power frequency withstand voltage meet the requirement ofitems 1 and2.

4.Little contact resistance of branch joint. The ratio value of contact resistance vs reterence resistance ofequal length branch line is equal to or less than 1.2;

5.Large joint short circuit strength. The variation rate of contact resistance ratio after short circuit is equal to orless than 0.2;

6. For ZR-YJV type flame-retarded prefabricated branch cable, self extinguishing time of jacket is equal to orless than 12s and meets GB/T18380.3;

7. Besides power supply in normal working condition. NH fire resistance type cable can reamin normaloperation for 90min under buming condition and meets GB/T19216.21-2003;

8.Max. working temperature of copper, core of VV type cable is 70'C and that of YJV type cable 90'C;

9.With excellent corrosive resistance. it can keep from eroding of inorganic salt, oil, base, acid, organicsolution and so on;

10. YJV type prefabricated branch cable has excellent themal stability and aging resistance;

11.GWDZ-, WDZA-, WDNA-, WDZAN-clean-type precast branch cable possesses the features suchas lowsmokelow-toxic,non-halogen and fire-resistance etc;

12.GZR-YJV oxygen barrier branch cable with high flame retardant and fire resistance that exceedsAntifaming Stamdard A class.

ProductWe will always adhere to the "mutual benefit and win-win" concept of cooperation, customer demand oriented,customer satisfaction as the goal, to provide customers with reliable products and super expected service.MORE

ProductWe will always adhere to the "mutual benefit and win-win" concept of cooperation, customer demand oriented,customer satisfaction as the goal, to provide customers with reliable products and super expected service.MORE

SolutionsProducts are widely used in power, communication, chemical, mining, metallurgy, transportation, petroleum, railway and other important fields.MORE

SolutionsProducts are widely used in power, communication, chemical, mining, metallurgy, transportation, petroleum, railway and other important fields.MORE ServiceWe will continue to take quality management as the core, high-tech as the guidance, with customers at home and abroad to establish strategic partnership, win-win cooperation, create a better future!MORE

ServiceWe will continue to take quality management as the core, high-tech as the guidance, with customers at home and abroad to establish strategic partnership, win-win cooperation, create a better future!MORE About UsPeople Electrical Appliance Group is one of China top 500 enterprise and Global Top 500 machinery company.MORE

About UsPeople Electrical Appliance Group is one of China top 500 enterprise and Global Top 500 machinery company.MORE