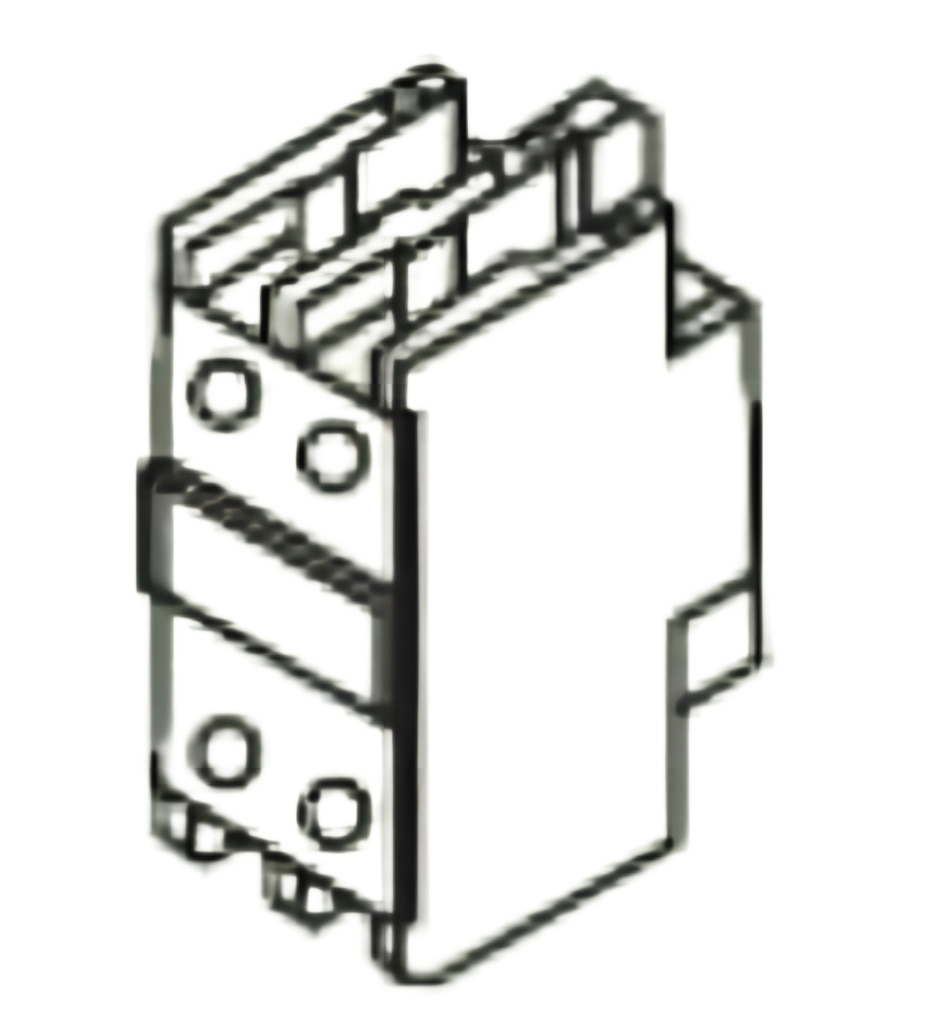

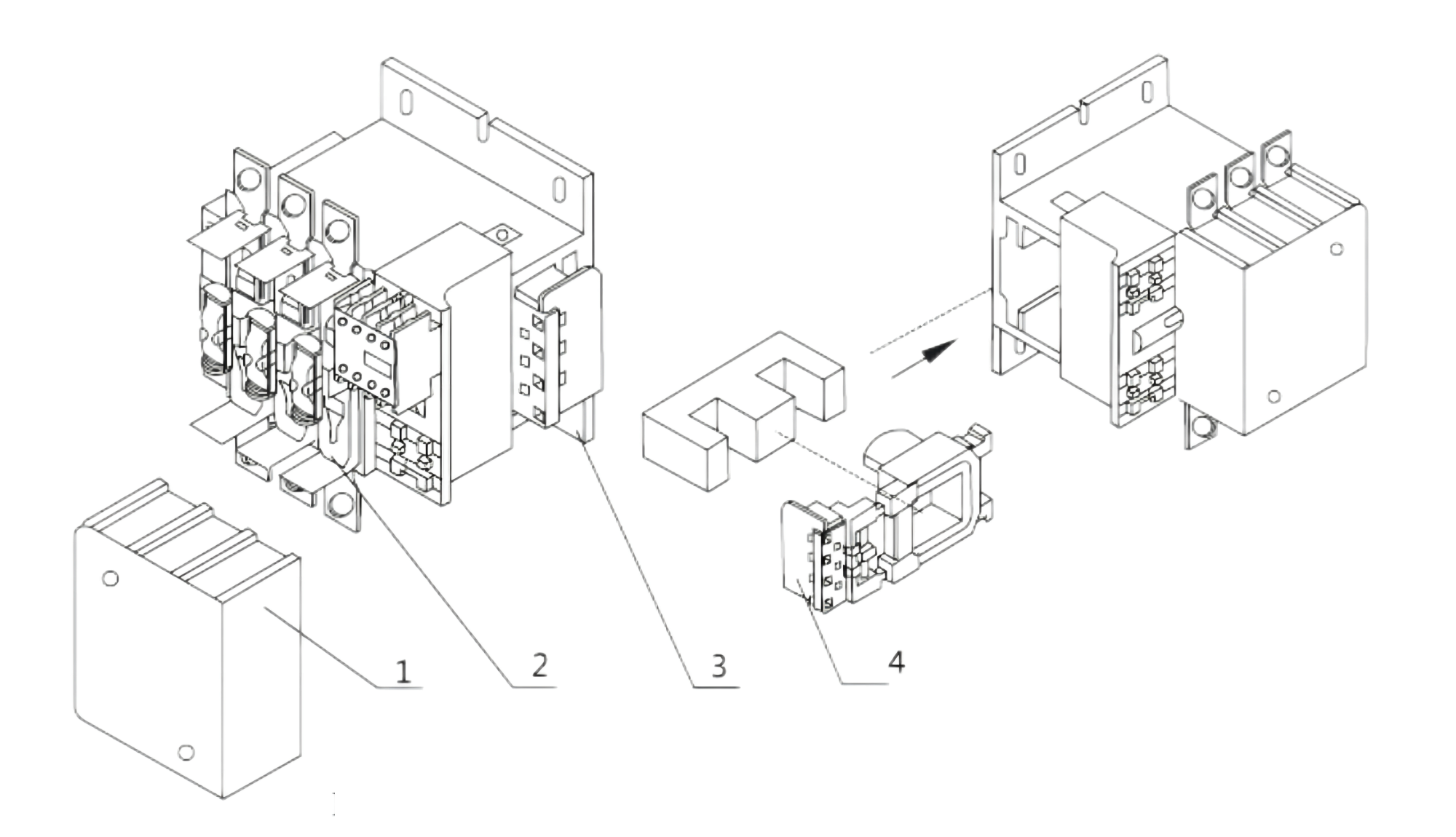

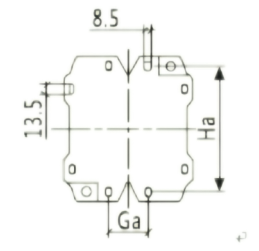

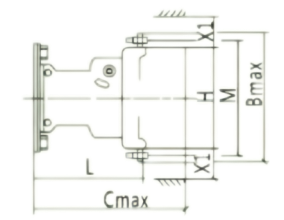

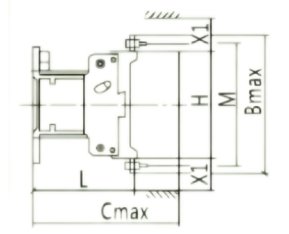

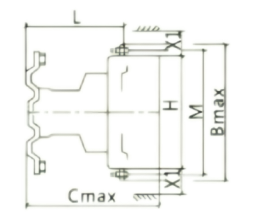

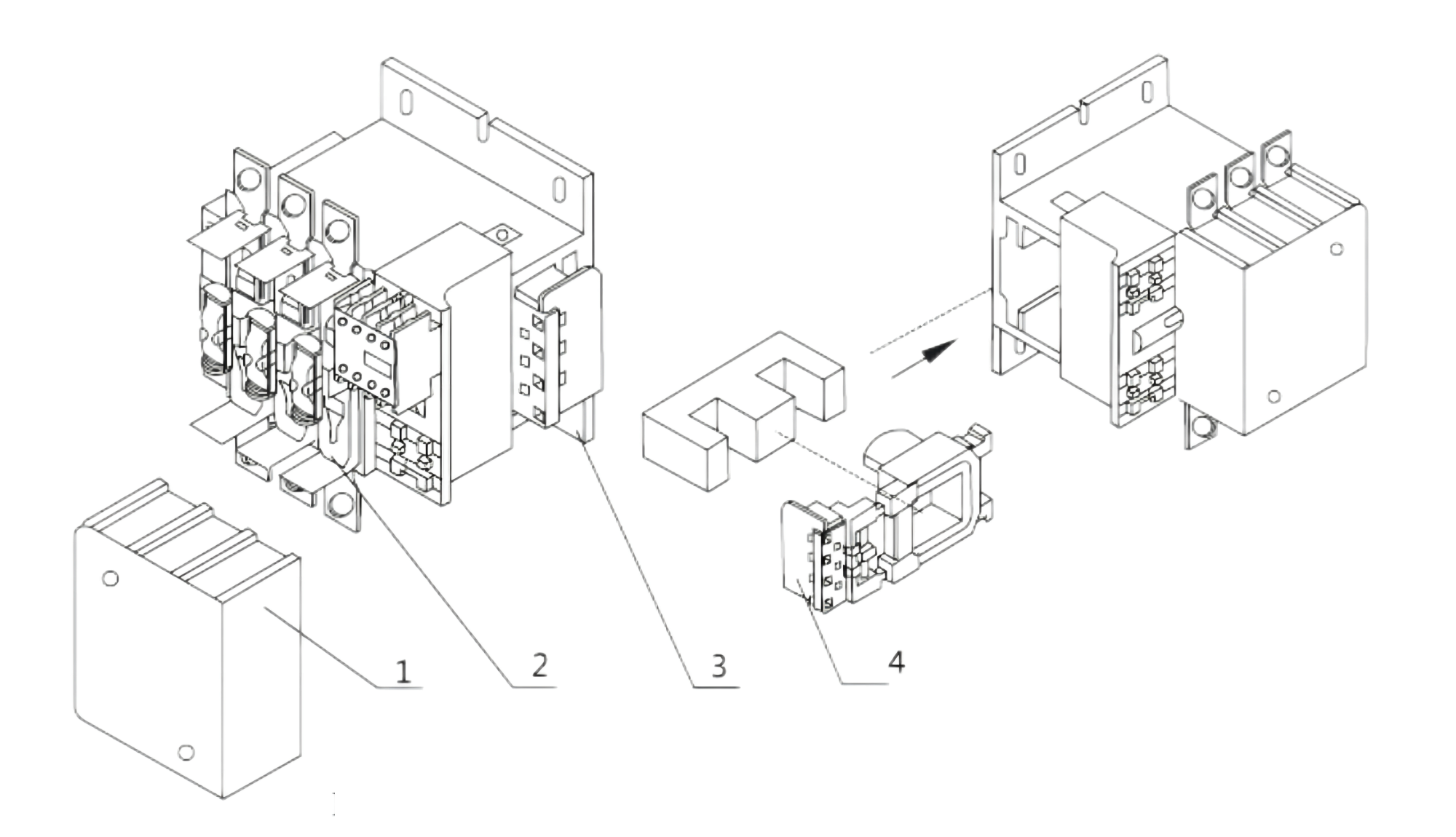

6.1 Contactor is mainly comprised of arcing system, contact system,baseand magnetic systeninclude iron core and coil) to see figure 1

| In picture: |

| 1 .Arcing systemn |

| 2.Contact syster |

| 3.Base |

| 4.Magnetic system |

Figure 1 General structure sketch map for CJX2-115~265 contactor

6.2 Contact system of the contactor is direct-acting, double breakpoint arrangement, the lower bastdopts the aluminum alloy material, the coil is the plastic sealing structure, and the coil is combined with a magnetic yoke into a whole, which can be directly taken out or placed in, it’s very convenient and maintenance. to see figure 1

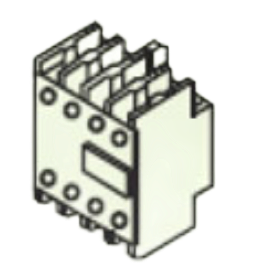

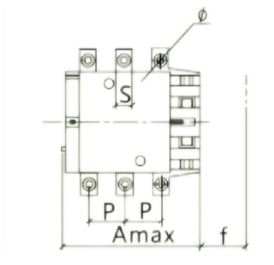

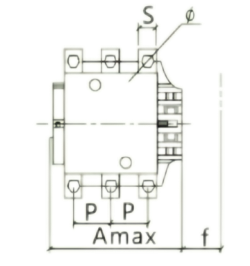

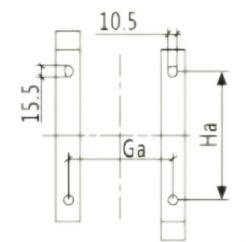

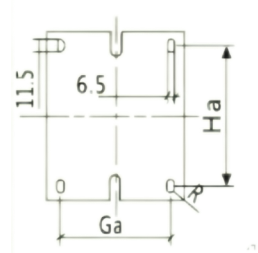

6.3 There are one couple of NO contacts inside the coil of contactor, which can be used as auto-local contact or signal contact; Additionally, it can be attached to equip with two auxiliary contact groups total of 8 couples contacts, see map 2. Combination information of auxiliary contact to see table 2

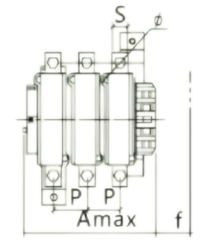

6.4 Small arcing distance of contactor, for example, the arcing distance of CIX2-115-330 is nearly 10mm (200-500V), which is one-sixth of another same capacity contactor. It is used for complete equipment can reduce the usage space, and is an excellent supporting component in power electric control equipment

6.5 It can be attached the auxiliary contact group, air delay contact, and other accessory by building block type installation mode to see Figure 2

6.6 Contactor can be attached with horizontal or vertical mechanical interlock and reciprocal interlocletween two pcs of vertical installation contactor.

6.7 Derivable two/four poles contactor

ProductWe will always adhere to the "mutual benefit and win-win" concept of cooperation, customer demand oriented,customer satisfaction as the goal, to provide customers with reliable products and super expected service.MORE

ProductWe will always adhere to the "mutual benefit and win-win" concept of cooperation, customer demand oriented,customer satisfaction as the goal, to provide customers with reliable products and super expected service.MORE

SolutionsProducts are widely used in power, communication, chemical, mining, metallurgy, transportation, petroleum, railway and other important fields.MORE

SolutionsProducts are widely used in power, communication, chemical, mining, metallurgy, transportation, petroleum, railway and other important fields.MORE ServiceWe will continue to take quality management as the core, high-tech as the guidance, with customers at home and abroad to establish strategic partnership, win-win cooperation, create a better future!MORE

ServiceWe will continue to take quality management as the core, high-tech as the guidance, with customers at home and abroad to establish strategic partnership, win-win cooperation, create a better future!MORE About UsPeople Electrical Appliance Group is one of China top 500 enterprise and Global Top 500 machinery company.MORE

About UsPeople Electrical Appliance Group is one of China top 500 enterprise and Global Top 500 machinery company.MORE